Control Scheme Modelling in Single Stage Evaporators

Timeline

September 2023 - December 2023

Client

Controls Class Final Project

Problem Statement

In tomato paste production and many other operations,

variations in feed and steam conditions can disrupt

product quality and energy efficiency.

This project models the dynamic behavior of a

single-effect evaporator in MATLAB and simulates

control strategies in Simulink to maintain solids

concentration and temperature within desired limits

under changing operating conditions.

Project Overview and Scope

Objective: Maintain product solids

concentration and temperature under changing

conditions.

Modeling: Developed mass, solids, and

energy balance equations; combined into a nonlinear MIMO

state-space model; linearized around steady state for easier

control design.

Implementation:

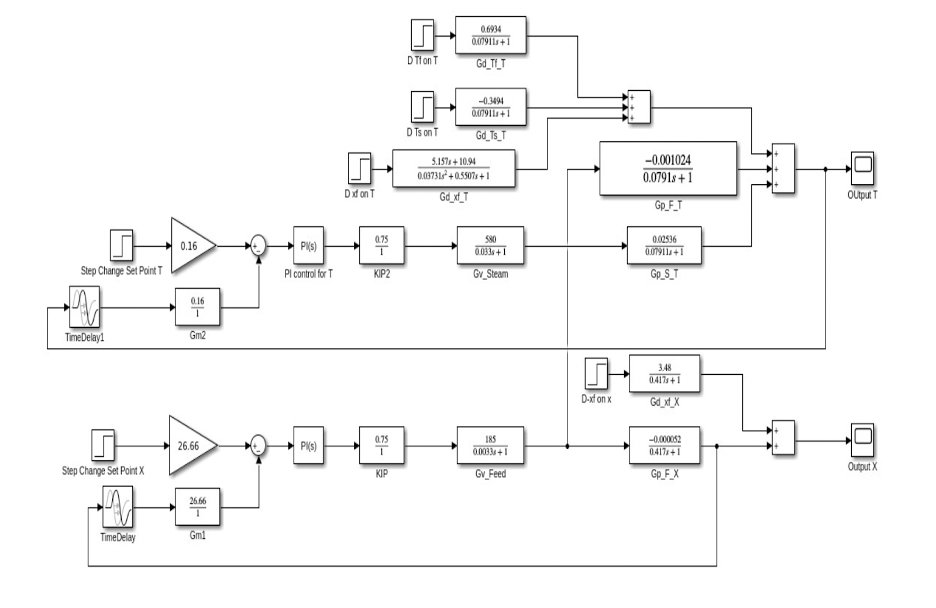

Used MATLAB to build the state-space model,

convert it into transfer functions, and design a control system.

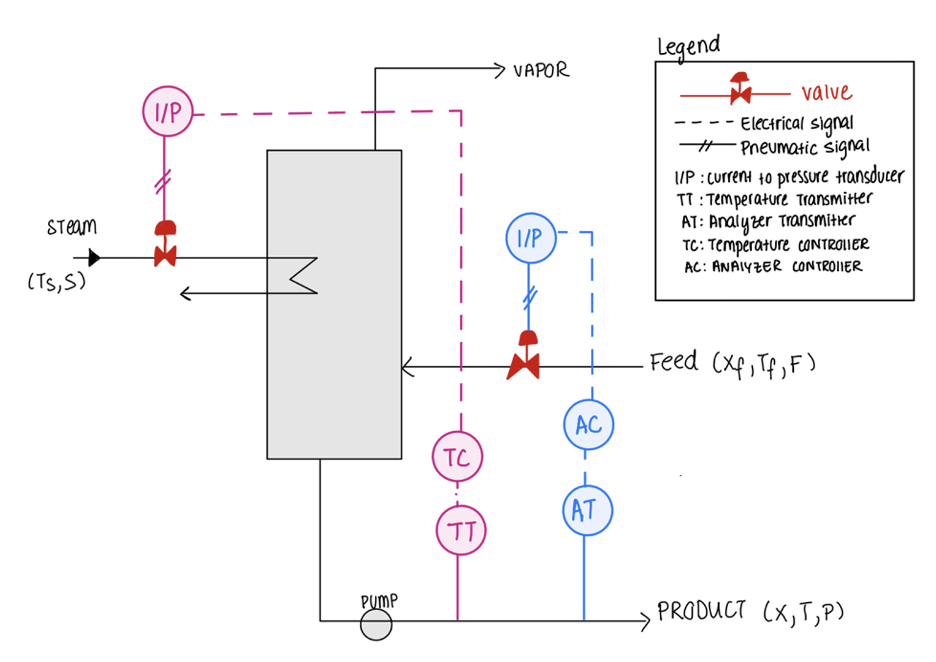

Simulation: Created the

control setup in Simulink, including valve,

transmitter, and transducer dynamics, to test

responses to setpoint changes and disturbances.

Sketch of Control Scheme

Tools and Applications Used

MATLAB- used for mathematical modeling using the

data from Simulink. Additionally used for steady state and transfer function derivations

using a state space model.

Simulink- used to implement a full control loop

simulation, allowing visualization of dynamic responses to setpoint changes and

disturbances in variables.

Final Simulink Control Scheme

Project Documents