Propylene Oxide Production Plant

Timeline

September 2023 - December 2023

Client

Chemical Engineering Capstone

Problem Statement

The growing global demand for propylene oxide, projected to reach $30 billion by 2026, presents a key opportunity for sustainable, mid-scale producers. This project aimed to design a cost-effective and environmentally conscious process to produce 100,000 metric tons per year of industrial-grade propylene oxide within a $1 billion capital budget.

Project Overview and Scope

Project Overview: Our team developed a detailed design

and economic analysis for a propylene oxide manufacturing

facility.

This project is centered on

transforming propene into high-purity propylene

oxide using the environmentally friendly

Hydrogen Peroxide to Propylene Oxide (HPPO) process.

Two Reactor System for Better Conversion

(From the HYSYS modelling)

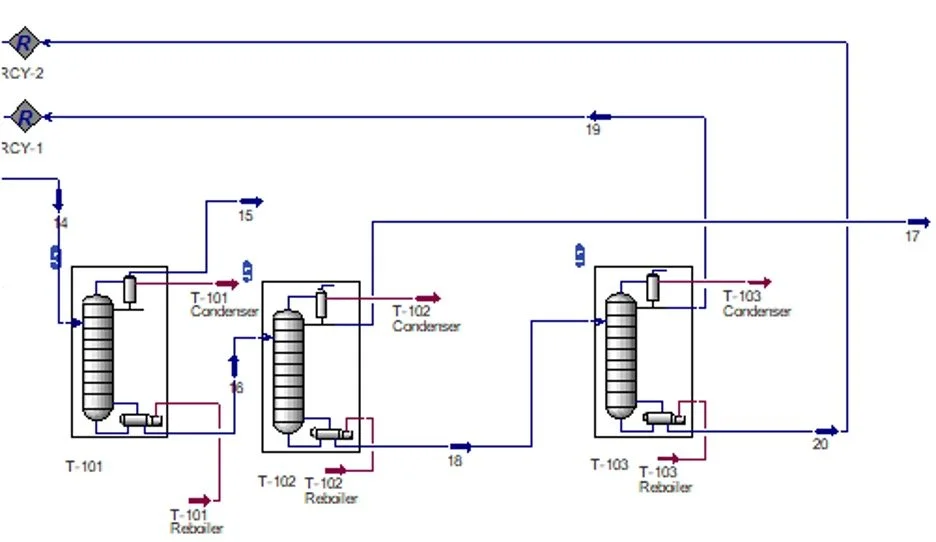

3 Step Distillation

(From the HYSYS modelling)

Design and Scope:

Location: Facility is located in Galveston, Texas, to leverage proximity to key feedstock suppliers and product markets.

Capacity: Designed to produce 100,000 metric tonnes of 99% pure propylene oxide annually.

Process: Facility employs a two-reactor setup , optimizing the conversion

and enhancing overall efficiency. The purification of the product involves a series

of three distillation columns

Sustainability:Water is produced as co-product. Sustainability is prioritized by recycling waste streams for

methanol recovery and energy reuse.

Economic Evaluation:Economic analysis indicates

challenges due to high feedstock costs and market

competition.

Tools and Applications Used

Aspen HYSYS- for simulation, reactor design and sizing, kinetics,

and separation.

Aspen Economic Analyzer- for eqipment cost analysis

Aspen Energy Analyzer- for energy optimization and heat exchanger analysis

GREET & Ecoinvent- for life cycle analysis (LCA)

Microsoft Excel- for general calculations and stream tables

Process Flow Diagram (PFD) of the final setup

(made with Visio)

Project Documents